We have always had a love of tiny places, and we don’t seem to be outgrowing it. Put that together with an urge to try out new building ideas, and our marginal building skills. The result has been – well, let’s just say – interesting.

We once lived in a Volkswagen camper on a hilltop park in Rome while I went to school. Thanks to a kind campground attendant, we got to be among the warmest people that winter in a city of cold stone-floored apartments when he let us run a long extension cord so we could have a little electric heater. We supplemented that little living space with a big tent which became our kitchen and dining room.

We will pass over the Volkswagen camper on top of which we tried to build a metal box that would hold water, and thus create a solar-heated roof.

Then there was the White Bird Trailer. We were doing handcrafts, and wanted a trailer to haul our wares and stay in at shows. We bought an inexpensive handmade trailer made out of 2”x2” wood framing, light plywood, and a covering of fiberglass sheets, but despite its lightweight materials, it was terribly unwieldy because its builder had constructed a sleeping compartment that overhung the hitch. Major surgery was called for. We cut off the overhang, put in windows, and by a stroke of luck the whole trailer became so well-balanced we could pick it up by its hitch and turn it around. That 7’x8’ trailer was to take the four of us – luckily the kids were little – across the U.S. pulled by a $100 Buick and be our home camping for 9 months on the California coast.

The first house we built in the forest, a process which we describe in The Treasures of Simple Living, (link) was 12’x36’ but felt big after that. It felt like a boat on which we were sailing off to discover our lives.

Building that house helped us discover what was to become our preferred way of building, for it was a pole house whose foundation was a series of treated poles set in holes in the ground. Everything for that house came straight from the lumberyard, but we were soon dreaming and experimenting in cutting and treating our own poles, and then using logs from our land for beams and rafters.

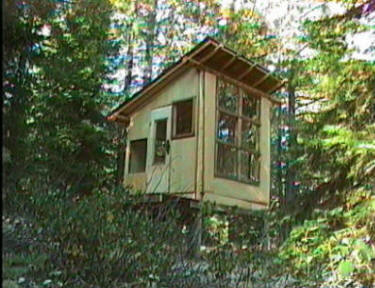

When we had been camping on the California coast, we had once supplemented the space of our little trailer with a meditation hut in the form of a giant cardboard refrigerator box. Hardly discrete. On the land we tried a more advanced version, which was a pyramid-shaped hut still made out of cardboard. That didn’t work very well, either. Eventually we built Tyra’s meditation hut, a building that has withstood the test the time including the heavy snowfalls that we can get here in the foothills of the Cascade mountains.

The poles, beams and rafters we cut ourselves, and the floor, roof and walls were plywood sandwiches filled with insulation. This worked out rather well, but our desire to use more natural materials was going to involve us in all sorts of complications.

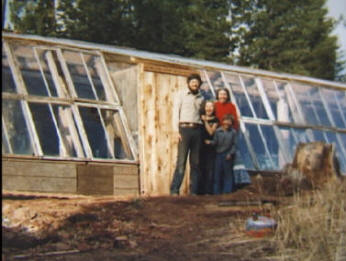

After we had built our original house, we got carried away and forgot to think small, and tried to create what we called a bioshelter, that is, a combination greenhouse/living quarters that was earth-sheltered on three sides. You can read about how that giant building failed in The Treasures of Simple Living.

We eventually replaced it with a small greenhouse/guesthouse with the same kind of pole and beam framing, but with straw bale walls. The fact that we were really slow in finishing the plaster of these bale walls should have told us something about our preferred style of building, but it didn’t. See Building Our Strawbale Greenhouse/Guesthouse Photo Gallery

On the travel front, we built a cab for our old pickup out of plywood which had a very nice roof in two pieces that opened up, but on the first lap of a trip to Mexico, one-half blew off, and we never did find it. We rebuilt the roof and kept on going.

We had a little Nissan hatchback, but it was cramped, to say the least, to try to sleep the four of us inside it. We built a box to ride on top of it like a luggage carrier, but big enough to sleep two. But it looked too much like a coffin, and the wind drag would have been excessive, so we never did use it.

Then came the Cube. We were exploring outback in Baja California with our Toyota 4-wheel-drive truck, and we did a series of trips in which we slept in the back which was covered by a standard camper shell on a sleeping platform. Talk about small places. It was a workout to try to get dressed in the morning since it was impossible to sit up.

What we really dreamed about was to somehow take a whole little house with us on these trips outback. Even little trailers, however, filled as they were with various tanks and fittings, were too heavy, as were fancy camper shells that would sit on the back of the truck. What we wanted was the tiniest of spaces that would still be big enough for a full-sized bed, miniscule kitchen, and potty, and allow us to stand up. Ideally its roof would lower down when we traveled, and the whole thing would fit on the back of our pickup, so we built the Cube whose name came from the fact that it was a little over six feet in every dimension. Creating the movable roof was the hardest part. In the first version, the roof and upper walls fit over the lower walls, but it turned out to be really too heavy to raise up and down. In the second successful version, the roof came off in two pieces, the walls folded down, and the roof bolted back on. To our surprise, given the small tolerances involved, everything fit together and it still continues to work. We would reach our camping spot in some faraway place, pop up the roof, sit on our bed and read a book, cook dinner, and enjoy a good night’s rest. See On the Road II

As I said before, we hadn’t really focused on why it was taking us so long to mud the straw bales in our little guesthouse, so when the chance came to build a tiny 10’x10’ studio, we decided to build it in our usual way, but incorporate some new ideas. The poles and their treatment, the beams and rafters, were all now standard operating procedure. This time, however, instead of cutting up old steel packing straps to fasten down the beams and rafters, we used a tow strap along with screws and washers. This appears to be a more elegant solution. We wanted to try to avoid creating rock or concrete footings for the bales, so we created a framework of rubber wood, that is, planks made out of a combination of ground-up tires and wood chips which we filled with old rigid foam insulation and covered with plastic and/or roofing roll. Then things began to get more difficult. I decided to wrap the whole building in bales so the walls were now outside the framing, and went right up over the roof instead of just using the bales to fill in between the poles. The thought would be that it would be better insulated that way. But since the bales were outside the framing, we needed to device ways of securing them to it, which we did with ropes made out of synthetic fibers.

For the roof we made a nice ceiling out of textured plywood panels, and put the bales, large side down, upon it. Then we covered it with a rubber liner, the kind that is used to create garden ponds, and lashed this down. Then along came a big wind – at night, naturally – and showed us how inadequate our lashings were. Finally we devised special clamps that held the liner in place.

Inside we put a rough coat of plaster over the bales, and called it good, and painted it white. It looked great, like some old Mediterranean farmhouse, but unfortunately, having the bales on the outside of the frame made it difficult to plaster them. The straw we got from a local farmer had been stored outside during the winter. We had tested it for moisture and it seemed fine, but perhaps even some of the inner bales that we took had gotten wet because they developed a strong odor which permeated the little room. We went back time and time again to try to reach all the cracks and crannies behind the framing in order to fully cover the bales, and to fill in all the innumerable holes we had left in our first rough coat. To make all this worse, the ropes holding the walls in place developed some slack, and the walls moved away from the framing. We were ready to dismantle this building, but we kept on going, and after a lot of hassle, the roof was secure, the walls were back in place, and the smell diminished, and we began to enjoy what is a very pleasant, cozy place. We built a small greenhouse on the front of it, using salvaged storm windows, but the first big wind caved that it, so we are redesigning that, as well.

The list of should-haves is a long one. We should never have gotten bales that were not under cover, or at least we should have brought them into an enclosed room to see what they smelled like. We shouldn’t have put the bales outside of the poles, or at least we should have mudded them before we did so. Perhaps we could have even mudded the bales while they were laying on the ground horizontally, and then put them into place and finished the job. We should have given the walls a second coat, or maybe we even should have forgotten the bales and made plywood panels filled with rigid foam, and been done in a fraction of the time.

In contrast to the endless detail work the little straw bale studio demanded, we built another experimental building in a weekend. It was an 8’x8’ temporary portable room in an unheated partially unfinished garage. It consisted of a floor platform made by 2”x3” filled with rigid foam insulation and covered with plywood that sat directly on the cement floor of the garage, and the walls and ceiling were made of rigid foam panels faced with aluminum foil on both sides, bolted to a framework of 2”x2”s. Its thermal properties turned out to be remarkable. Once warmed up, it would stay at a comfortable temperature heated by body heat. One important caution is in order. This kind of foam, polyisocyanurate, is not made to be used in exposed positions because of the fire hazard.

Conclusions? Small spaces appeal to some people more than others. A lot of it has to do with temperament. But for those people they do appeal to, it can save them considerable time, energy and money. Why build a bigger house when a smaller one will do? But there are more important lessons to be learned here. By now you realize that we are not great builders, but despite all our mistakes, building our own buildings has given us a wonderful sense of freedom. We know that in some way, no matter where we are, we can put some sort of roof over our heads. And despite our many building failures, we still feel there is not enough experimental building going on. Contractors and would-be homeowners, not to mention the banks that finance them, all feel they can’t afford to make a mistake, and so experimentation, when it does take place, tends to be minor and cosmetic, and what we get are countless stud wall buildings in the U.S., and cement block buildings elsewhere. What we need, however, is a new renaissance of building imagination that would employ both high and low tech materials. Imagine, for example, a building made of preform structural panels that simply bolted or snapped together. This seems eminently possible. Imagine, for example, rigid foam panels with metal mesh on both sides that are fastened together to form the walls and roof of a building, and then covered with stucco. Then you have a building method that is being pioneered by tridipanels.com. Couldn’t these panels be covered with adobe or cob, as well? Or imagine low tech panels made out of straw or other agricultural and forest waste.

The final lesson to draw from our bumbling building skills? If we can enjoy living in a house we made ourselves, why can’t you? If we can try to invent our little building methods, why can’t we as a society come together and create some truly innovative, inexpensive and enjoyable ways to house ourselves?